Accretion Power supplies the North American utility industry and global OEMs with high quality standoff insulator and busbar insulator varieties. Multiple manufacturing plants in the US and India, will assist OEMs with numerous standard and custom products. Discover the ways our new products, sizes, and materials can deliver cost effective solutions.

Accretion Power has a broad array of electrical insulators for utility and industrial applications, including porcelain, cycloaliphatic epoxy and composite. They offer low voltage and hard to find medium voltage post insulators, cycloaliphatic epoxy or porcelain feedthrough insulators. In addition, there is a full range of porcelain and composite bushings, roof bushings, and insulating busbar support standoffs for all types of outdoor applications.

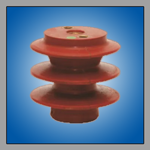

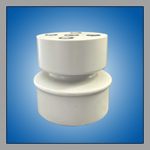

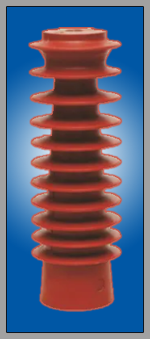

Standoff Insulators, Feedthrough Insulators

We specialize in busbar and standoff insulators. Our insulators provide high cantilever and tensile strengths, as well as torsion and compression pressure strength with corresponding resistance to erosion and long performance life. They are designed to meet or exceed all North American and International application standards. We also will custom engineer solutions to unique operating conditions or special application requirements.

Epoxy Insulators

Epoxy insulators offer higher tolerances from impacts versus porcelain and are very unlikely to shatter under mechanical or thermal pressures. The basic integrity of Epoxy ensures steady performance even when the surface is damaged. Epoxy insulators are very economical, lightweight and have high tensile strength. Outdoor cycloaliphatic epoxy insulators can withstand extreme temperature variances and are preferred for applications where UV, pollution or dampness are factors.

Our epoxy feedthroughs allow for a very high density and provide wide ranging design flexibility in allowing various types of conductors and connections. Epoxy is not as limited as other materials when considering its coefficient of thermal expansion (CTE) and it can create low-profile hermetic seals in tight spaces and is much lighter in weight. Epoxy feedthroughs are capable of withstanding hazardous locations and are sealed against, liquids, pollution, gases, and dust in wide temperature ranges.

Accretion Power Products:

Insulators

Epoxy, Porcelain or Composite

Epoxy Insulators:

Low voltage post 600V to 7.2kV

Medium voltage post 12kV to 36 kV

Voltage detecting 3.3kV to 36kV

Composite Insulators

Solid Core Post – 15kv -420kV

Line Post – 69kv – 230kV

Longrod – 15kV -1,200 kV AC

-320kV – 765kV DC

Porcelain Transmission

Hollow Core – Up to 1,200 kV

Solid Core Post – Up to 765 kV

Line Post -15kV to 69kV

Longrod/Disc – Up to 765kV

Various bus bars

Can accommodate various configurations and OEM specific designs

Dimensions

Silver-plated

Bare copper

Insulated

Std 12” sticks in various sizes, including tin plated

Primary Roof, Transformer & RMU bushings

Epoxy terminal and oil seal bushings

Feed through bushings

Feed through bus bar support

Epoxy feedthroughs

For any additional assistance, please contact us at sales@hilltech.com or 847-255-4400. Also, check out our website at: https://hill-tech.com/. You can submit a request for a quote directly by using our automated request system.