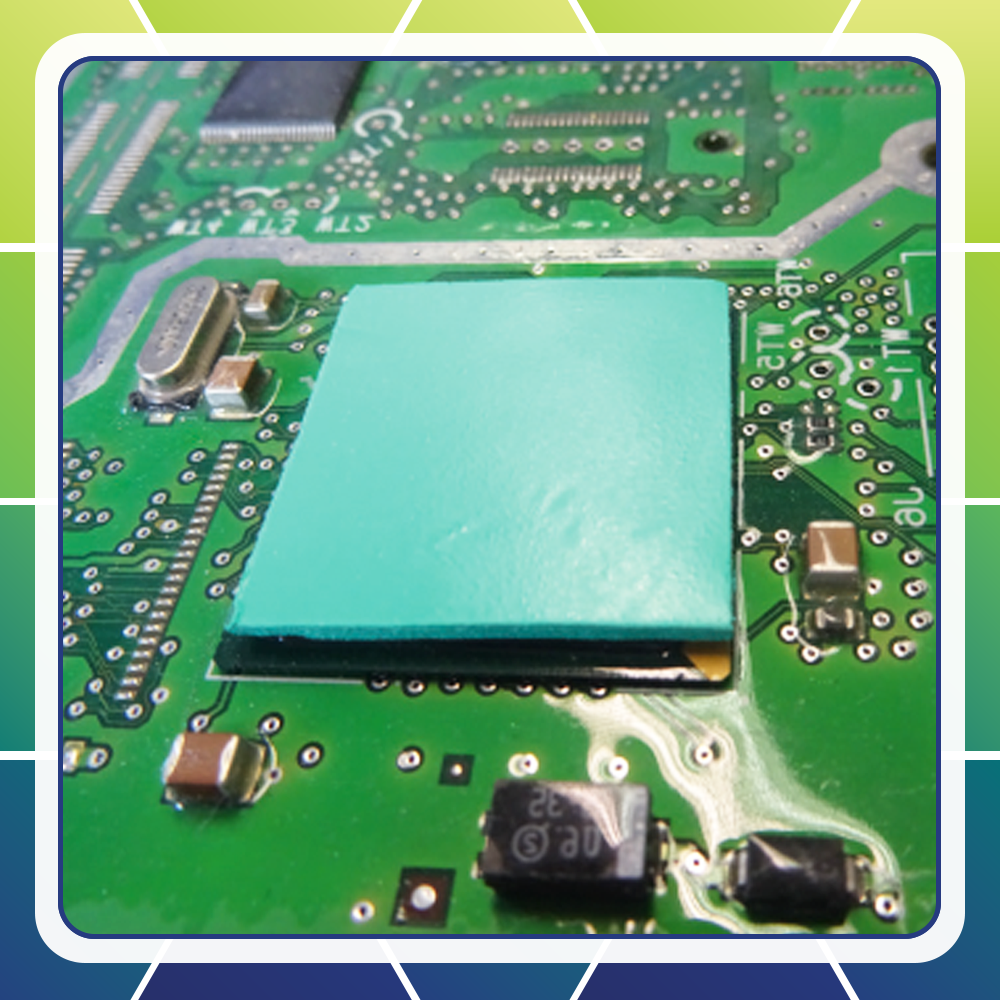

Electronics are becoming more compact, faster, and powerful as they advance, and are bringing new complex challenges surrounding heat dissipation/thermal management and electromagnetic interference (EMI). The latest innovation from Kerafol® is here to help: let us introduce you to KERABSORB™.

KERABSORB™ is a new class of hybrid elastomeric material that combines the functionality of thermal interface materials (TIMs) with high-performance EMI absorbers, creating a single, easy-to-integrate solution.

The Difference

Today’s high-density designs (such as 5G infrastructure, autonomous vehicle radar, and consumer electronics) have increasing data rates while physical spaces between antennas and ICs are shrinking. This can lead to rising component temperatures, increased risk of EMI, and signal degradation and performance losses. KERABSORB™ solves all three of these in one material.

All-in-One Advantage

Unlike conventional gap pads or absorbers, KERASORB™ materials can perform multiple roles at once:

- Efficient thermal conductivity: dissipates heat away from sensitive components

- Electrical insulation: enables safe operation even in high-voltage environments

- EMI attenuation up to 77 GHz: provides robust shielding against interference such as signal distortion and cross talk issues, which are increasingly prevalent in high-frequency designs like 5G and radar systems

Thanks to Kerafol’s innovative material formulation, KERASORB™ achieves EMI suppression without sacrificing electrical insulation. This is a significant advantage over many other competing products.

Product Highlights

KERASORB™ also has an EMI performance that remains consistent regardless of material thickness, is made of a soft and elastic material that adapts well to surface irregularities and has a high breakdown voltage that ensures robust electrical isolation. For more information check out this data sheet and view the chart below.

| Feature | KERABSORB 2500 | KERABSORB 1500 |

| Color | Mint | Orange |

| Thermal Conductivity (W/mK) | 2.5 | 1.5 |

| Dielectric Breakdown Voltage (kV) | 5.0 | 5.0 |

| EMI Attenuation (dB) | >40 | >40 |

| Hardness (Shore 00) | 35–50 | 30–45 |

Choose KERASORB™

KERASORB™ is a next-generation thermal interface management solution which is ideal for engineers and OEMs who need to balance heat, EMI, and space constraints without compromising on reliability or performance. If you’re designing for high-frequency, high-density environments, KERASORB™ is the solution that can simplify your thermal and EMI strategy all in one layer.

Contact Us!

Need help with selecting the right grade or integrating KERABSORB into your design? Contact Hill Technical Sales today to speak with a specialist. Visit our website and submit a quote at https://hill-tech.com/, contact us at 847-255-4400, fax us at (847) 255-0192, or email us at sales@hilltech.com. And be sure to look at our social media pages, linked below!