ARLINGTON HEIGHTS, ILLINOIS, USA, Friday, January 15, 2010: Hill Tech Sales, a leader in Components for Thermal Management and Electrical Power Conversion today posted information on standard heat pipes to increase working size in a cold plate.

Most times engineers will look at the standard 30cm length of heat pipe and dismiss using it in an application because their working distance is beyond 30 cm. The same occurrence also applies to heat dissipation being over the rating of a single heat pipe.

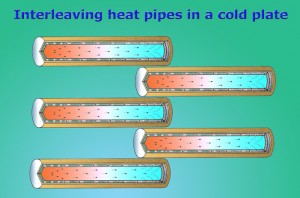

Heat Pipe interleave in a cold plate

Both of these issues can easily be addressed by using a properly designed heat pipe assembly. The first issue of length is easily addressed by interleaving heat pipes in a plate assembly with a nominal amount of overlap, in many cases 2 to 3 cm.

The second issue of enhancing thermal dissipation can be addressed by using the round heat pipes in a flattened state, stacking them side by side in an assembled plate. Since the heat pipes themselves are rather inexpensive, it is good design practice to add additional pipes to improve your design margin.

Note another inherent advantage in this concept is that this assembly now has improved built-in reliability through redundancy of heat transfer devices in the unlikely event of a single heat pipe failing.

For more questions on this article contact:

Vince Hill

Hill Technical Sales

216 West Campus Drive

Arlington Heights, IL 60004

Tel: +1- 847-255-4400 ext 12

Fax: +1-847-255-0192

You may also visit: http://www.hilltech.com/