ARLINGTON HEIGHTS, ILLINOIS, USA, Friday, August 31, 2012: Hill Tech Sales, a leader in Components for Thermal Management and Electrical Power Conversion today posted information on standard heat pipes to increase working size in a cold plate.

In the past engineers would not consider heat pipes for high power, power electronic applications for many reasons:

- Low maximum heat energy transfer capacity – only 70 watts – 8mm tube OD.

- Low temperature operation, (below the freezing point of water.

- Limited working distance of 30 cm.

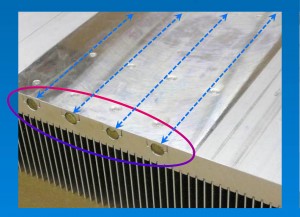

Heat Pipe spreading in a bonded fin heat sink

With new heat pipe advancements tube OD’s of greater than 16mm can be built, allowing for heat energy transfer in the kilowatts, assemblies with capacity of 32kW or more can be made.

Other innovations include:

- Antigravity Heat pipes with temperature ratings of +5 to +275 C

- LTSC – low temperature Heat pipes with temperature ratings ·40 to +30″C

- Diode type for heat transfer primarily in one direction

- Variable conductive Heat pipes for self regulation and automatic temperature control

- Flat profile for heat spreaders

- Loop Heat pipes

Heat pipes in a heat exchanger assembly provide heat transfers with no pumps are moving mechanical parts adding to system reliability.

Enhancing thermal spreading in high energy density regions can be addressed by using the flat profile heat pipes and fabricating them, stacked side by side in an assembled plate. Since the heat pipes themselves are rather inexpensive, it is good design practice to add additional pipes to improve your design margin.

Note another inherent advantage in this concept is that this assembly now has improved built-in reliability through redundancy of heat transfer devices in the unlikely event of a single heat pipe failing.

For more questions on this article contact:

Andrew Hill

Hill Technical Sales

216 West Campus Drive

Arlington Heights, IL 60004

Tel: +1- 847-255-4400 ext 12

Fax: +1-847-255-0192

You may also visit: http://www.hilltech.com/