ARLINGTON HEIGHTS, ILLINOIS, USA, Friday, September 7, 2012: Hill Tech Sales, a leader in Components for Thermal Management and Electrical Power Conversion today posted information on cold-plate using internal extruded liquid channel paths.

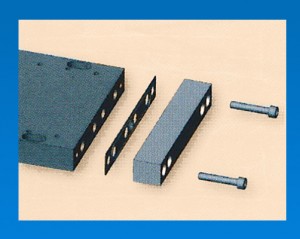

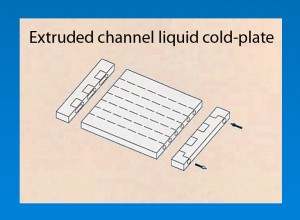

This is a construction example showing the extruded liquid channel base, with gasket interface and manifold connections

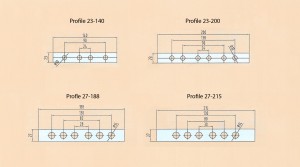

Choose among these four standard extruded liquid channel aluminum heat sink bases, in order to create your own custom configuration. Liquid cooled cold-plate can be up to 60 inches long.

This is a highly advanced, dependable liquid cooling technology utilizing internal liquid channels extruded into the cold-plate. No longer is expensive drilling and fabricated processes required. This extrusion technology overcomes past size limitations and comes in four standard sizes; lengths up to 60 inches!

These can be configured in a number of parallel and series flow options provide an optimal thermal solution. The liquid channels locations were determined in order to accommodate almost all power semiconductors. In addition, we can enhance thermal performance by using specifically designed turbulators which increase the flow rate in the fluid channel with only a minute increase in back pressure. Custom designed can a provided for specific thermal challenges.

We also provide other advanced thermal dissipation solutions:

- VBA – Vacuum brazed cold-plate assemblies

- Friction Stir Welding for air-cooled and liquid cooled cold plates

- Copper cold plates

- Heat pipes for High power industrial use: 30kW + heat pipe assemblies

- Heat exchangers

- Air-cooled bonded fin

- Air-cooled pressed fin

For more questions on this article contact:

Andrew Hill

Hill Technical Sales

216 West Campus Drive

Arlington Heights, IL 60004

Tel: +1- 847-255-4400 ext 12

Fax: +1-847-255-0192

You may also visit: http://www.hilltech.com/